Print FDM - The Future of Business

The Power of Print FDM for Metal Fabricators and 3D Printing

In today's ever-evolving world of technology, businesses need to adapt and innovate to stay ahead. The combination of metal fabrication and 3D printing has given rise to a groundbreaking technology known as Print FDM. Businesses in the Metal Fabrication and 3D Printing industries can now harness the power of Print FDM to elevate their operations to unprecedented heights.

What is Print FDM?

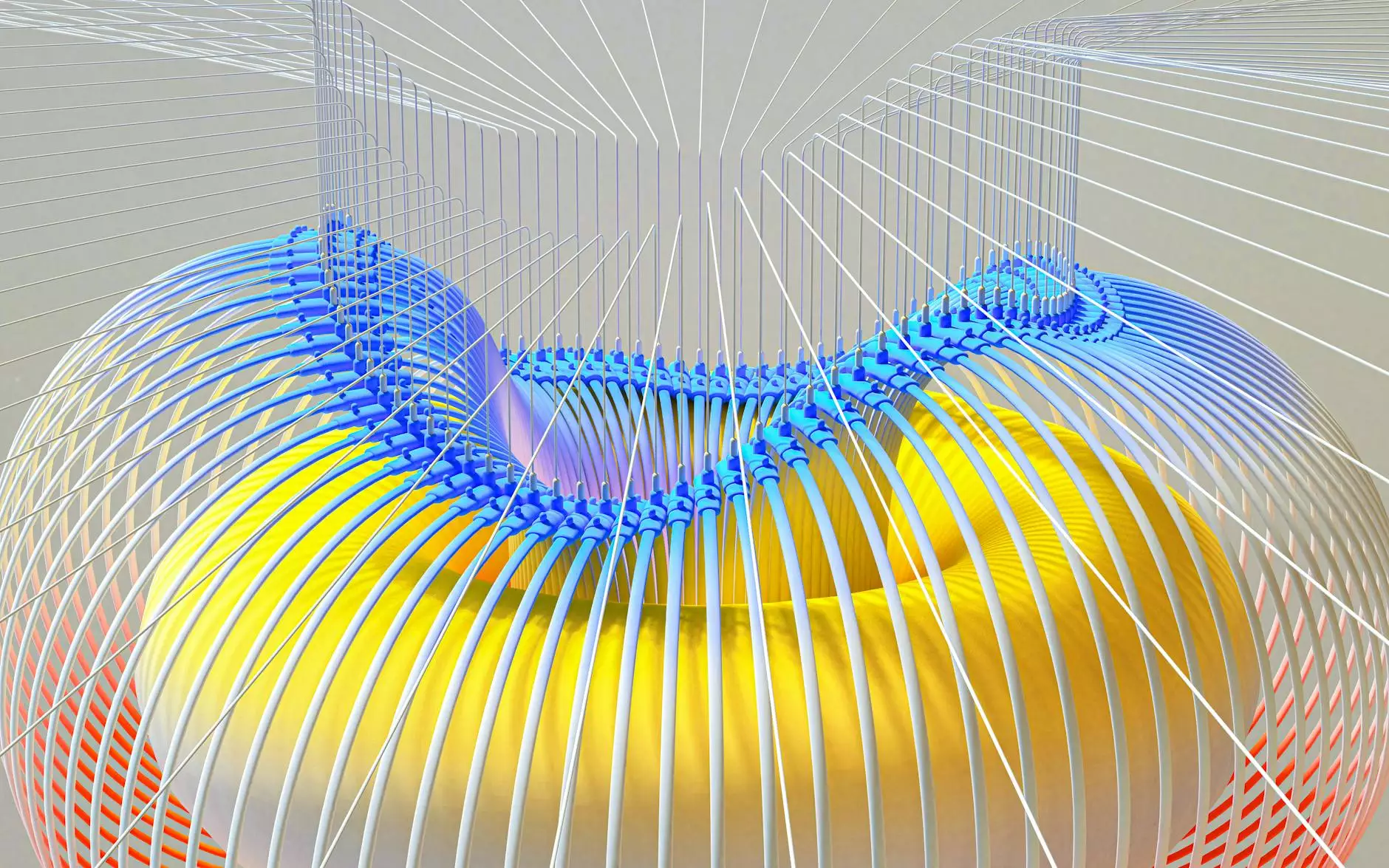

Print Fused Deposition Modeling (Print FDM) is a cutting-edge 3D printing technique that utilizes a continuous filament of thermoplastic material to create highly precise and complex objects. The process involves melting the thermoplastic material and extruding it through a print head, layer by layer, forming the desired shape. The result is a durable, reliable, and cost-effective product that can be manufactured with exceptional precision.

Enhancing Metal Fabrication with Print FDM

Metal Fabricators have long been at the forefront of innovation. With the advent of Print FDM technology, Metal Fabricators can now push the boundaries of what is possible. By integrating Print FDM into their workflows, Metal Fabricators can unlock a multitude of benefits:

1. Customization and Personalization

Print FDM enables Metal Fabricators to create highly customized and personalized products. From intricate designs to unique shapes and sizes, Print FDM offers unparalleled freedom for creativity. This level of customization opens up new opportunities for Metal Fabricators to cater to niche markets and meet individual customer demands with precision.

2. Rapid Prototyping

With Print FDM, Metal Fabricators can accelerate the prototype development process significantly. The ability to quickly produce functional prototypes helps businesses save time and resources. Metal Fabricators can identify and rectify design flaws early on, ensuring a seamless transition to the production phase.

3. Cost-Effectiveness

By leveraging Print FDM technology, Metal Fabricators can optimize their production costs. The versatility of Print FDM allows the use of thermoplastic materials, which are generally more affordable compared to traditional metals. Additionally, the reduced material waste and streamlined production process contribute to overall cost savings.

4. Complex Geometries

Traditional metal fabrication techniques often face limitations when it comes to creating complex geometries. With Print FDM, Metal Fabricators can effortlessly manufacture intricate designs and geometries that were previously unattainable. This capability expands the range of applications, from aerospace components to architectural elements, allowing Metal Fabricators to stay ahead of the curve.

The Impact of Print FDM on the 3D Printing Industry

As 3D printing continues to revolutionize industries, Print FDM stands as a game-changer in the field. The benefits of Print FDM extend beyond metal fabrication, influencing the future of 3D printing as a whole:

1. Mainstream Adoption

Print FDM bridges the gap between traditional manufacturing and 3D printing. Its compatibility with commonly used thermoplastic materials makes it accessible to a wider range of businesses. With the versatility of Print FDM, more industries can fully embrace the potential of 3D printing technology, propelling it into the mainstream.

2. Speed and Efficiency

The speed and efficiency offered by Print FDM technology have undoubtedly transformed the 3D printing landscape. Print FDM enables faster production times, allowing businesses to meet tight deadlines without compromising on quality. This increased efficiency opens up possibilities for mass production with unprecedented levels of accuracy.

3. Sustainable Manufacturing

Print FDM reduces material waste significantly compared to traditional manufacturing techniques. With its precise layer-by-layer approach, businesses can optimize material usage, minimize environmental impact, and embrace more sustainable manufacturing practices. Print FDM technology aligns with the global push for eco-friendly solutions.

Partnering with QuickParts.com

When it comes to harnessing the power of Print FDM for your Metal Fabrication and 3D Printing business, QuickParts.com is your trusted partner. Our expertise and cutting-edge technology ensure that you can make the most of Print FDM to propel your business forward.

At QuickParts.com, we offer a comprehensive range of Print FDM services tailored to meet the specific needs of Metal Fabricators and 3D Printing businesses. Our seasoned team of experts is well-versed in the intricacies of Print FDM and can guide you through the entire process, from design optimization to production and post-processing.

Through our state-of-the-art facilities, we deliver exceptional quality, precision, and reliability in every Print FDM project. Whether you require custom metal components or intricate 3D printed designs, we have the capabilities to bring your vision to life.

Partnering with QuickParts.com gives you the competitive edge. Stay ahead in the Metal Fabrication and 3D Printing industries with our Print FDM solutions that redefine what is achievable.

The Future is Print FDM

Print FDM represents the future of Metal Fabrication and 3D Printing. Embracing this groundbreaking technology allows businesses to unlock unparalleled opportunities for growth, customization, and efficiency. With QuickParts.com as your trusted partner, you can navigate the dynamic landscape and seize the advantages offered by Print FDM. Experience the transformative power of Print FDM and revolutionize your business today.